CNC Machining

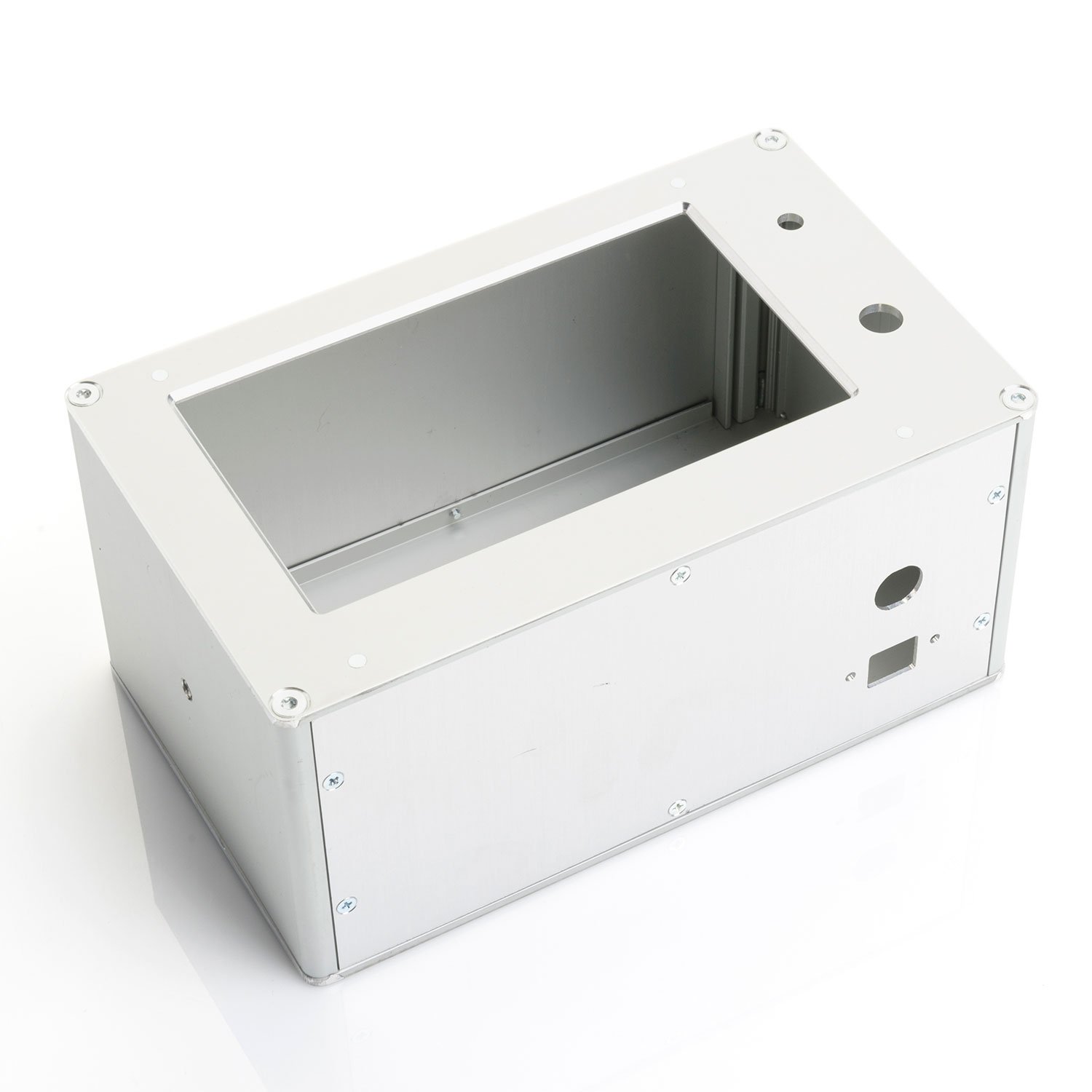

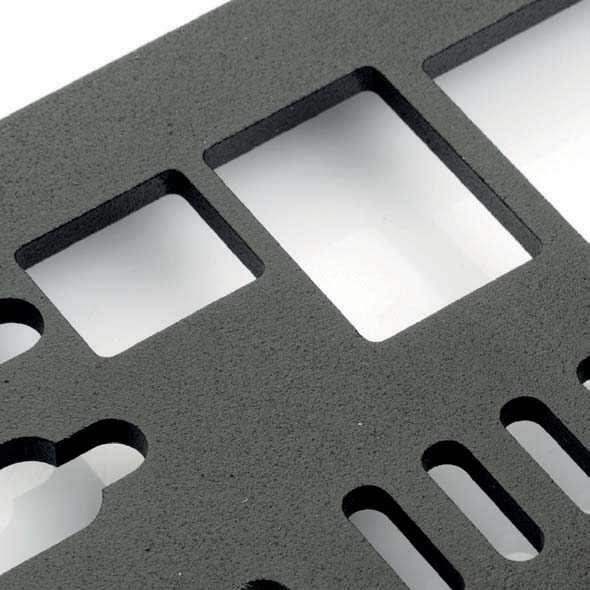

For years, we have been customizing our enclosures as per our customers' requirements. In this regard, attention and accuracy are the key elements for manufacturing our enclosures from raw materials such as plastic, aluminum, extrusion, sheet metal, and aluminum castings.

Thanks to the industrial computer-controlled CNC machines and our lasting experience, all of your components such as circuits, terminal blocks, LCD displays, and keypads easily and precisely fit into our enclosures.

Techical Drawing

Send your PDF, DXF, DWG, STEP or hand-drawn design.

Workmanship

After the technical drawing is approved, the workmanship is started with the product-specific workmanship code (Ex: C-2001-001).

Control

A picture of the finished sample is shared with you and your approval is obtained.

Recieve Your Product

Once your product is ready, it is delivered quickly.

Operation at Every Geometry

We can customize our enclosures with various geometrical shapes and dimensions.

No Minimum Order Quantity

No matter is your order is composed of 1 piece, we are committed to customize it.

Impeccable Worksmanship

With the guidance of our expert staff, we process every surface of your enclosure fast, precise and without any damages.

Cutting Tolerances

We can process your enclosures within ± 0,1 mm of tolerance.

More Than 30 Years of Experience

Our experienced staff will assist you to get the best results.

Technical Support

We provide you with technical support to make sure our product exceeds your expectations.

Waste-Free Production

We cover the potential waste that may result from the production process.

By means of the computer controlled machining, we can process all geometric shapes

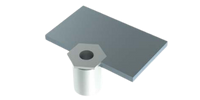

Circular Cutting

Curved Cutting

Label Pool Emptying

Flat / Countersunk

Rectangle Cutting

Chamfering

Customized CNC Cutting Code

We save your CNC cutting and UV & Laser printing codes into our systems. Thus, we accelerate our processes once you wish to repeat your previous order.

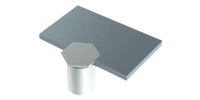

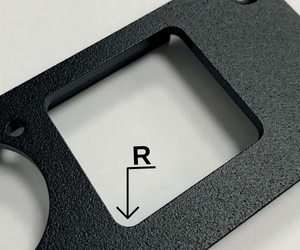

Corner Radius

When a rotating tool is used, the corners of the machining shapes are rounded in proportion to the tool lenght.

Sharper corners are possible using a smaller tool, but this increases our machining time and cost.

| Material | Standart Radius | Minimum Radius |

|---|---|---|

| Plastic | 1,00 mm | 0,75 mm |

| Transparent Panel | 1,25 mm | 1,00 mm |

| Aluminum | 1,25 mm | 1,00 mm |

| Sheet Metal | 1,25 mm | 1,00 mm |

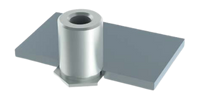

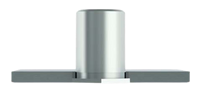

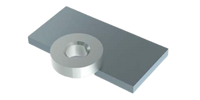

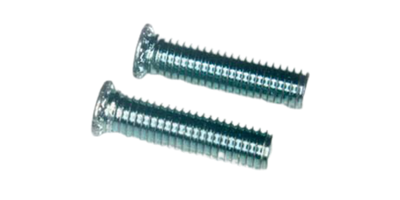

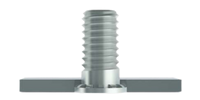

Countersinking

| Size | Countersink Thickness (C) mm | Material Thickness (T) |

|---|---|---|

| M2 | 1,20 mm | 1,20 mm |

| M2,5 | 1,45 mm | 1,45 mm |

| M3 | 1,75 mm | 1,75 mm |

| M3,5 | 2,00 mm | 2,00 mm |

| M4 | 2,30 mm | 2,30 mm |

| M4,5 | 2,55 mm | 2,55 mm |

| M5 | 2,80 mm | 2,80 mm |

| M6 | 3,30 mm | 3,3 mm |

| M8 | 4,40 mm | 4,4 mm |

Countersinking is cutting the top of the screw hole at an angle so that the head of a screw fits on the mounting surface without protruding.

If the countersink thickness of the screw is greater than the thickness of the material to be machined, the excess can be left on the upper or lower surface.

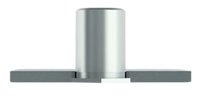

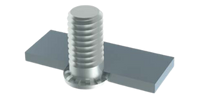

Threading

When mounting components such as connectors and cable glands in enclosures we can also thread the enclosure surface with special

tools instead of drilling straight holes and using nuts. You can find the thread lengths and pitches we cut in accordance with PG and Metric

standards in the table

| Measurements | Pitch |

|---|---|

| M2,5 | 0,45 mm |

| M3 | 0,50 mm |

| M4 | 0,70 mm |

| M5 | 0,80 mm |

| M6 | 1,00 mm |

| M7 | 0,50 mm |

| M8 | 0,75 mm |

| M8 | 1,25 mm |

| Measuremets | Pitch |

|---|---|

| M10 | 0,75 mm |

| M10 | 1,00 mm |

| M25 | 1,50 mm |

| M32 | 1,50 mm |

| M40 | 1,50 mm |

| M50 | 1,50 mm |

| M63 | 1,50 mm |

| Measurements | Pitch |

|---|---|

| PG7 | 1,27 |

| PG9 | 1,411 |

| PG11 | 1,411 |

| PG13,5 |

1,41 |

| PG16 |

1,411 |

| PG21 |

1,588 |

| PG29 |

1,588 |

| PG36 |

1,588 |

| PG42 |

1,588 |

| PG48 |

1,588 |

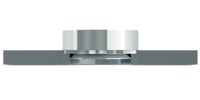

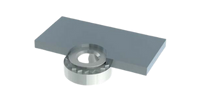

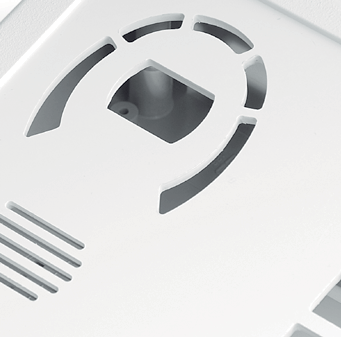

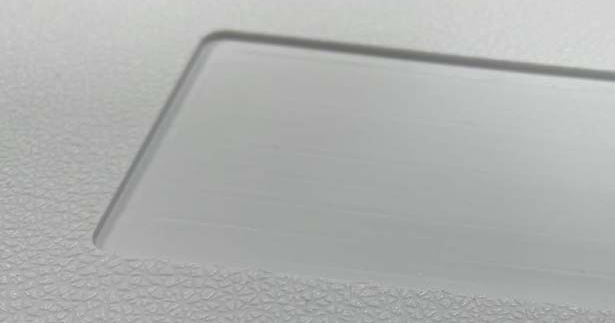

Recessed Area for Membrane Label

Recessed area at the desired depth

Recessed area at the desired depth Recessed area can be applied on the metal surfaces

Recessed area can be applied on the metal surfaces Enclosures can be machined to stretch

so that switch caps do not puncture the

label

Enclosures can be machined to stretch

so that switch caps do not puncture the

label

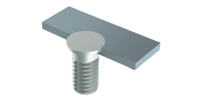

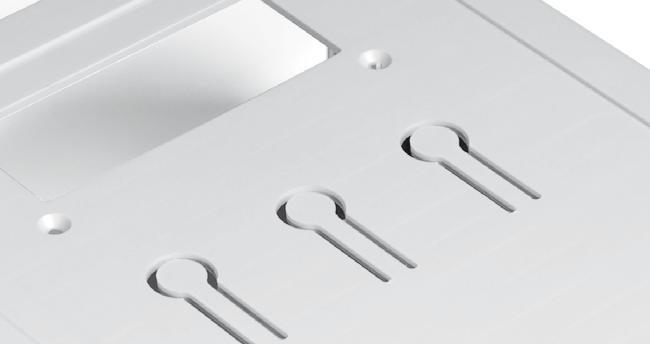

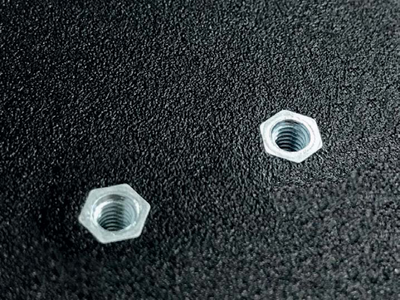

Clinching Fasteners

Fastening nuts, screws and elevation parts are components that enable all kinds of device and card assembly to be made more robust and

durable.

Specially produced fastening nuts, screws and standoffs are pressed into the holes previously drilled on soft metal with a special press

with high pressure.

For aluminum and metal surfaces

Robust and durable

Threaded mounting feet at desired height

Precision work with parallel compression method

High torque resistance

Does not require any extra holes or threads

Reasonable cost and clean workmanship

Screw, Nut, open and closed mounting feet

M3, M4, M5 and M6, M8 sizes

Upgrade Steel Parts (Open) SO Models Compatibility with M3, M4, M5 sizes |

|

|

|

|

Upgrade Steel Parts (Close) BSO Models Compatibility M3, M4, M5 sizes

|

|

|

|

|

Drive in nut (Steel) S Models Compatibility with M3, M4, M5, M6, M8 sizes |

|

|

|

|

Driven Screw (Steel) FH Models Compatibility with M3, M4, M5, M6, M8 sizes |

|

|

|

|

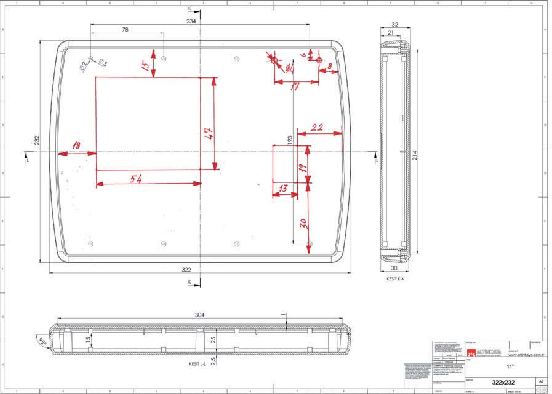

Instructions and File Formats for CNC Cutting

You may send us your instructions about CNC cutting in different ways.

You can send processes you want by drawing manually or on the computer on technical pictures of PDF or DXF format is found on our website.

Hand-drawn or computer-drawn sketch of the process 2/3 dimensional technical drawing. You can also see 2/3 D file formats in table 2.

If you do not have any technical drawings,you are able to send

sample of your product to us. Necessary drawings will be send after

doing according to sample.

During production step, once you send your PCB, and components such as connector, terminals, lcd screen with us, the assembly of the components will be checked then, sizes and tolerances will be corrected for a better performance.

⚠️ Please make sure the file scale is 1/1.

You can share hand drawn sketches on product drawing with us.

| Size | Countersink Thickness (C) mm | Material Thickness (T) |

|---|---|---|

| Hand-Drawn Sketch | 2 Dimensional | pdf, jpg, png, tif |

| Autocad Drawing | 2 Dimensional |

dxf |

| PDF Drawing | 2 Dimensional |

|

| Step | 3 Dimensional |

stp, step |

| Parasolid | 3 Dimensional |

x_t |

| iges | 3 Dimensional |

igs |

Technical Drawing for CNC Cutting

While dimensioning the technical drawing, the center point will be determined first and then the measurement values will be given or the measurements should be made from the points that can be measured with a caliper on the box should be given. The following sample drawings can be

used.

Tolerances

Even though there is a high sensitivity of CNC machines, please avoid giving exact tolerances for plastics as being elastic materials.

Please find general tolerances using the following.

Tolerances DIN7168

| Nominal Dimensions (mm) |

0,5 - 3 | 3 - 6 | 6 - 30 | 30 - 120 | 120 - 400 |

|---|---|---|---|---|---|

| Median | ± 0,1 |

± 0,1 |

± 0,2 |

± 0,3 |

± 0,5 |